PDPiPr Metalchem-Warszawa S.A.

The PDPiPr Pump and Pumping Station Selection Program, as the name suggests, is a program for optimizing the operation of pumping stations based on pumps manufactured by Metalchem-Warszawa S.A. Intuitive operation and advanced calculation methods allow very accurate simulation of pump and pumping conditions. We start work with the selection program already with a minimum amount of data. You can choose from many types of tanks, discharge pipelines and inside pumping stations as well as all our pumps. We can also determine the calculation methods according to the Polish Standard, Colebrook-White or others. For less advanced users, automatic selection is recommended, for more advanced ones, manual selection of all parameters, giving infinite possibilities of estimating results.

Program support

- Instalation

- Choice of operating mode

- Type of pumping station

- Pressing parameters

- Tank selection

- Pump selection

- Results

- Printing report

- Settings

- Help

1. Instalation

The program can be installed from a CD attached to our catalogs or downloaded directly from our website, then we will be sure that the installed version is the latest, stable version and containing all pumps currently produced by us. To install and run the PDPiPr program, it is necessary to have the BDE (Borland DataBase Engine) program installed to support Borland databases. Some computers install it themselves among system updates, but some require it to be installed manually, fortunately it can be downloaded from the internet without any problems.

Download programm

2. Choice of operating mode

After starting the program, we are greeted by a green screen with the name of the program and our company logo. In the upper left corner we have the menu:

- Database

- Works

- Options

- Window

- Help

- Database

- Pumps

- Metalchem S.A.

- Pumps

- Tasks has a submenu:

- Pump Selection

- Work point

- Universal pump system

- Selection of pumping stations

- Sewage pumpig stations PMS

- Rainwater pumping stations PMD

- Open

- Pump Selection

- Option – printer settings and program start

- Window – window display method

- Help

1-a-I

Electronic form of the pump catalog

2-a-I

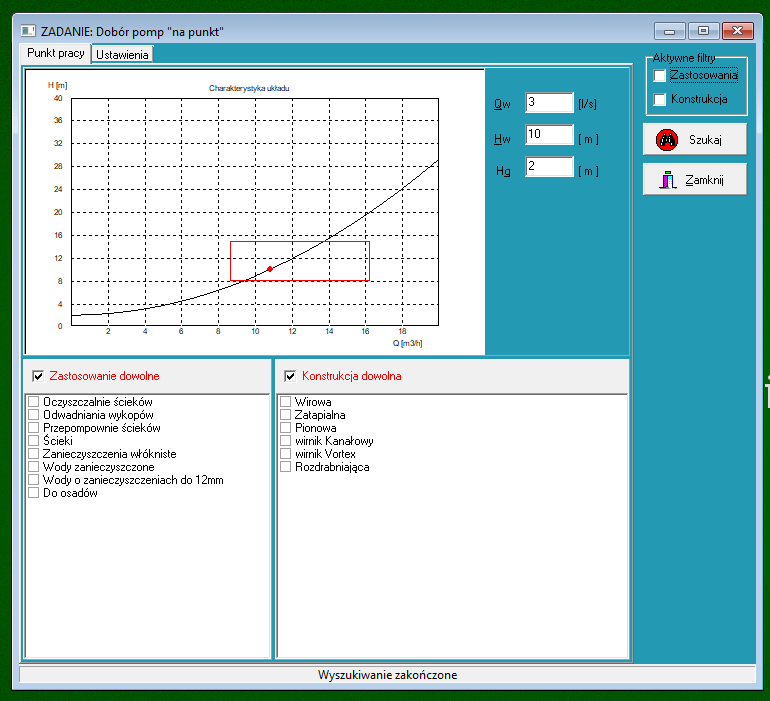

Pump operating point – tab for quick pump search with known requirements for pump performance and operating pressure.

2-a-II

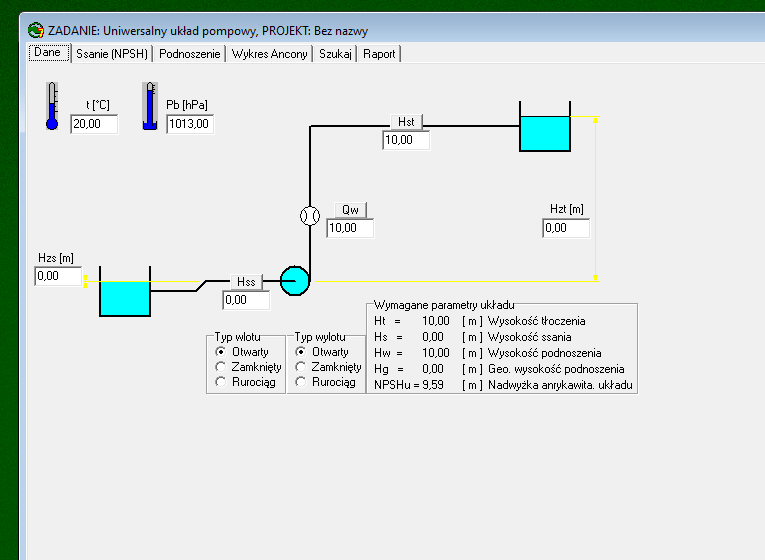

Universal pumping system – the possibility of simulating liquid parameters and pumping

2-b-I i 2-b-II

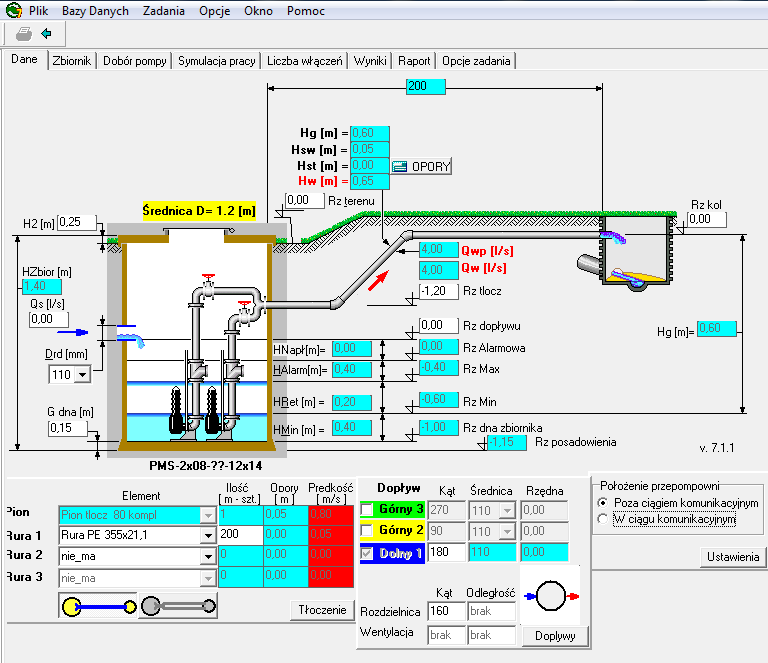

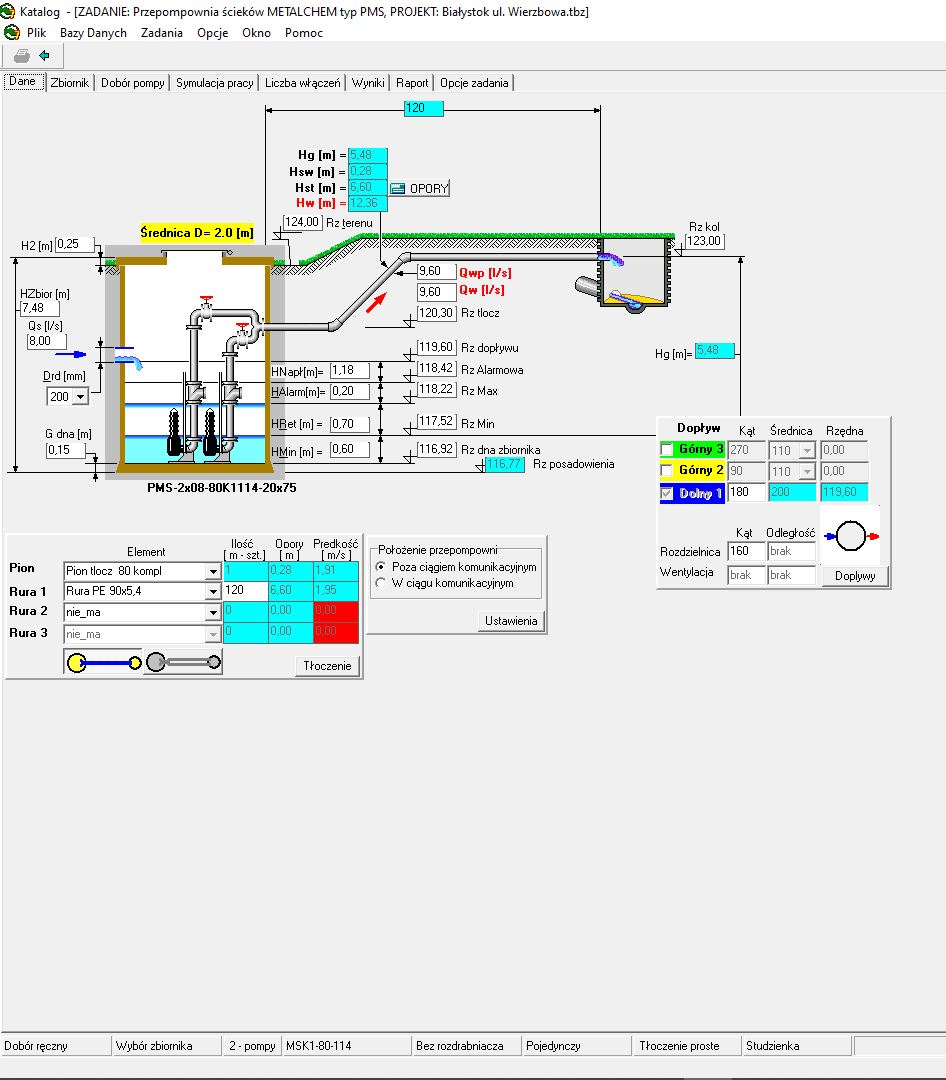

Selection of PMS sewage pumping stations and PMD rainwater pumping stations – an extensive pumping system enabling infinitely large number of pump and pipeline simulations as well as size and height of tanks, simple and left-hand pumping systems and many other options.

Depending on the operation mode of the pumping station, whether as sewage or rainwater, the mode of controlling levels and switching on the pumps is changed.

Because this part of the program is the most complex and has the most options, we will focus on it in the current presentation.

Manual work, automatic work

The program allows us to choose pumping stations in two modes (automatic) (basic) and manual (advanced). Less advanced users should focus on automatic settings, due to the fact that the program then selects the values recommended by the pump and reservoir manufacturer and allows the user to model inflow and ordinate values. Working in manual mode gives you much more possibilities to set individual parameters, but it can sometimes lead to calculation errors when you enter one of them incorrectly.

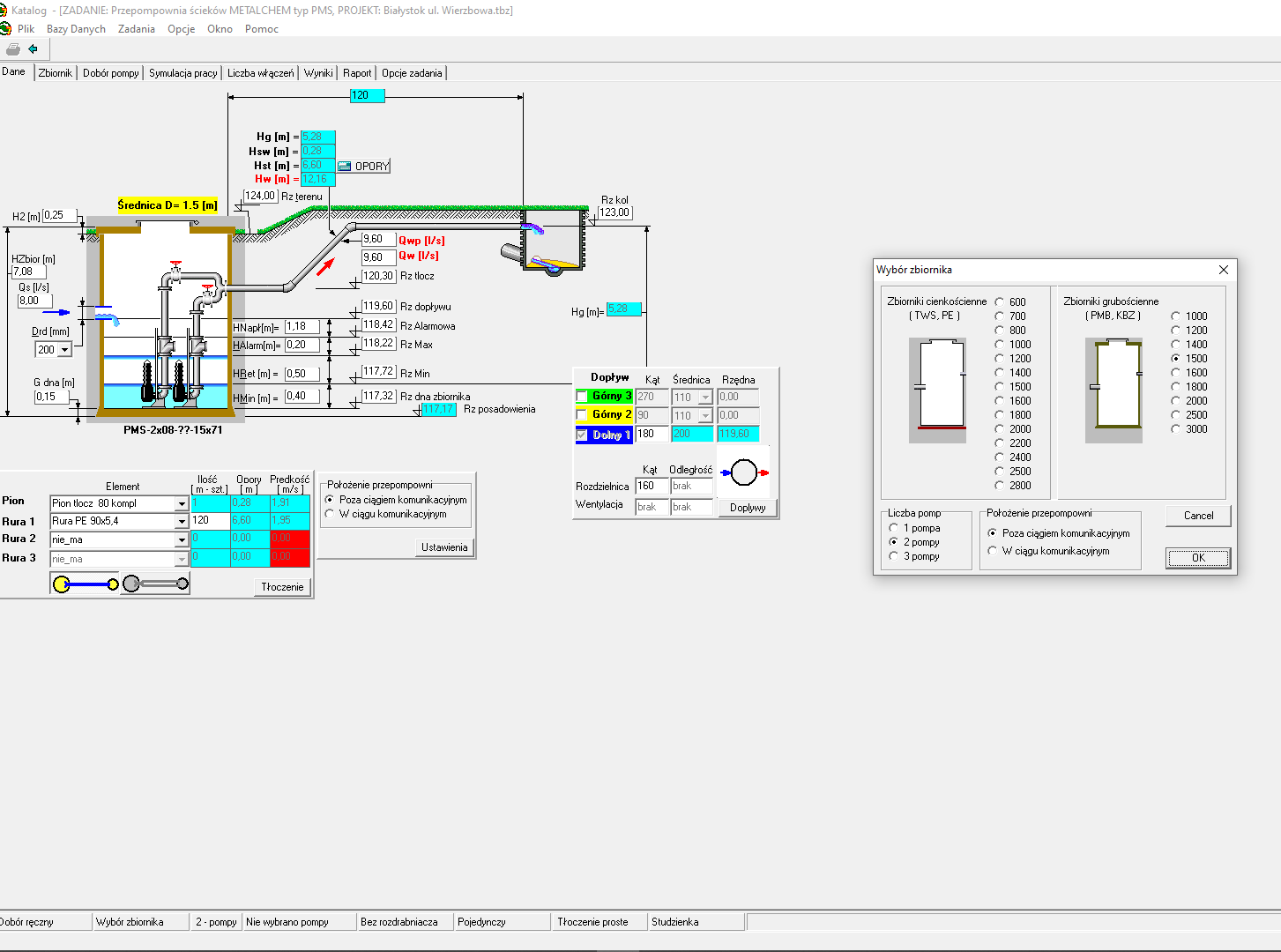

Tank selection

Most often, the selection of the tank is carried out in automatic mode, because the thickness of its walls and the material from which it is made for the calculation of pumps does not matter much. Its internal dimensions are important, allowing us to determine retention and individual levels of control.

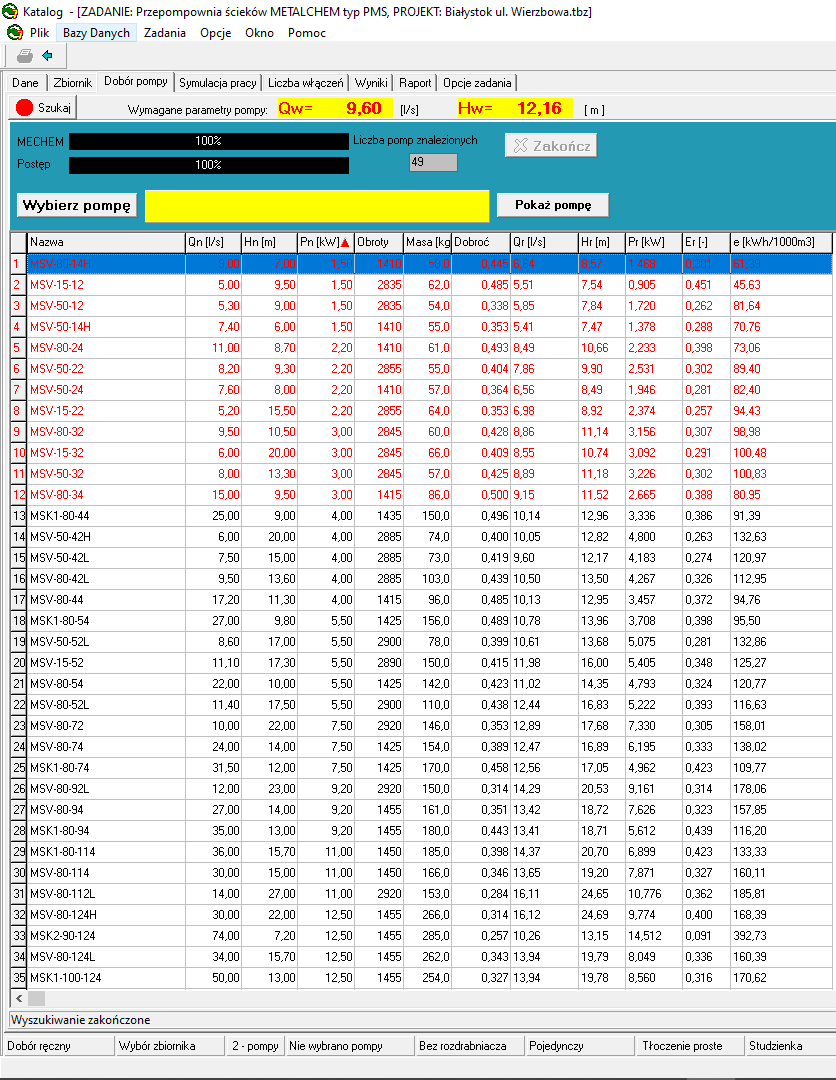

Choosing the right pump

The program does not select pumps on its own, but only suggests which are in the calculation range and shows them in black, pumps in red are similar in parameters, but do not meet the exact criteria of the task. The correct selection often requires analysis of various solutions in order to select the best pump in terms of parameters (low power, excess pressure or efficiency, small size, appropriate lifting speed on the pipeline), but sometimes other parameters such as the type of sewage (water) dirty, raw sewage, mechanically treated sewage, etc.) or e.g. unification of pumps on the user’s network so that he can use the pumps interchangeably with other pumping stations.

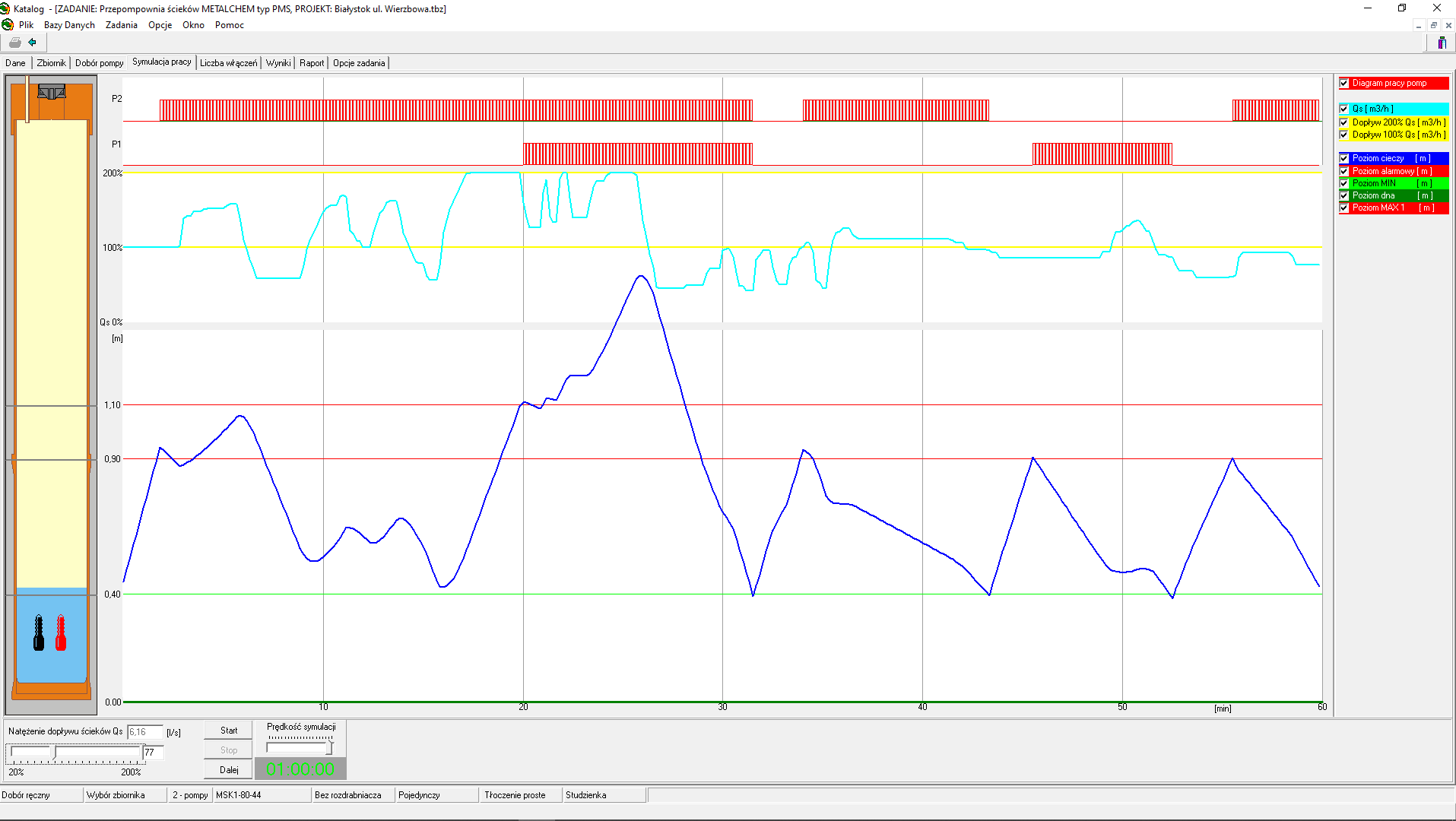

Simulation

After selecting the pump, we can go to the simulation tab, where by manipulating the parameters of the daily flow rate distribution we can check individual cases of the selected pumping station. For example, how increasing the inflow will change the frequency of pump starts.

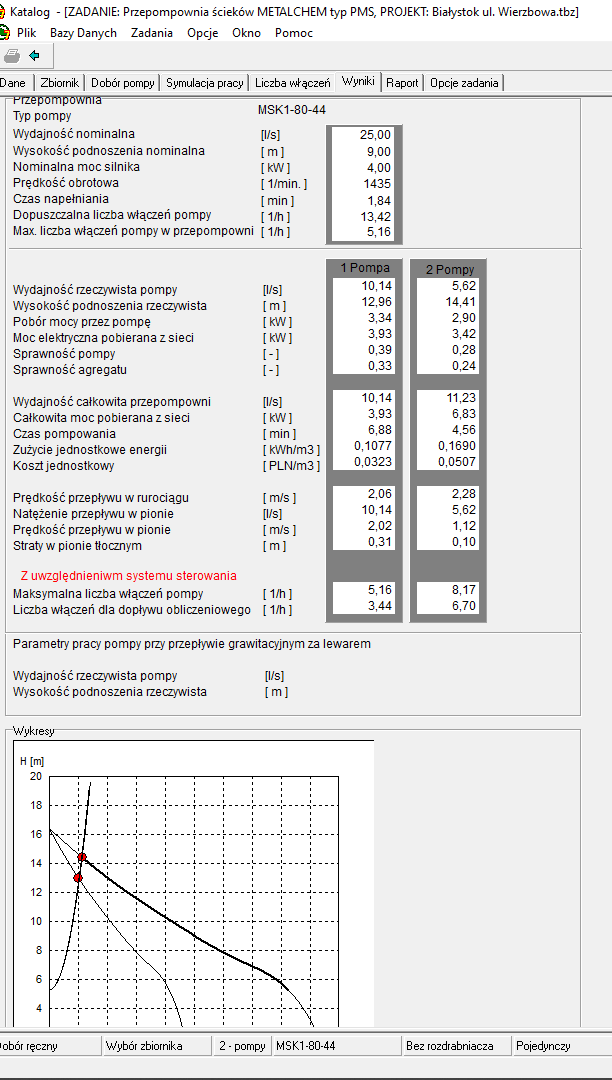

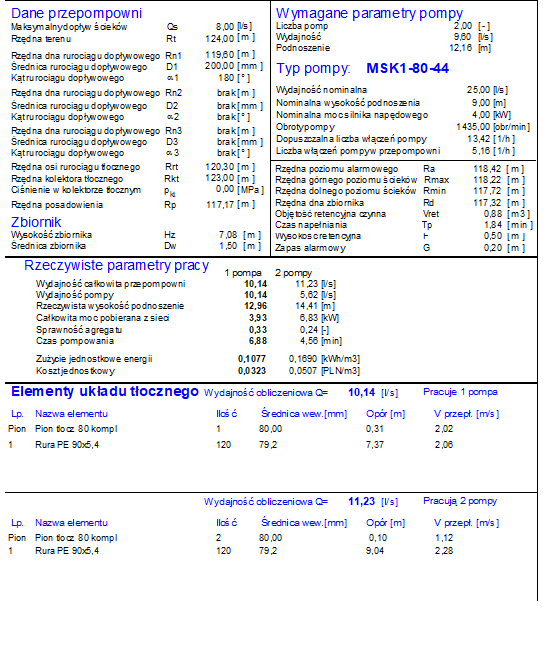

Results

Table with the results of the calculation of the pumping station operating parameters, pressure and pump capacity with one pump running, two or more, the effect of pump power on the output (restrictions in the capacity of the pipe), etc. We can also analyze the approximate cost of 1m3 pumping / sewage or energy consumption by pumps.

Report

At the end, the program allows us to generate a report with all parameters of the pumping station and discharge pipelines, an orientation diagram of the pumping station and charts of pump performance and hydraulic losses on the discharge pipeline. The data generated by our program are necessary for projects and are very accurately reflected in the operating parameters of pumps in real delivery systems. Thanks to such calculations and owned test characteristics of each of our pumps, we are able to determine the discrepancies between the design and the actual delivery system on the customer’s network.

For proper selection, sometimes it is necessary to change the pumps several times or model with the parameters of inflow or flow of pumps and pumping stations, respectively. Individual versions can be saved as * .tbz files and later edited using our program.

2-c

Open – opens the saved database of the selection program.

Other options of the main menu are used only for simple changes in the visual operation of the program. Important program changes, e.g. the m3 / h to l / s converter, can be found in the selection options for individual pumping stations.

Help in using the program

For those interested, we conduct training: by phone, on-line or arrange meetings. We help in installing and learning the program. The program is free and very comprehensive, it is still developing and is constantly being supplemented with new pumps and their characteristics.