Propeller and ejector mixers

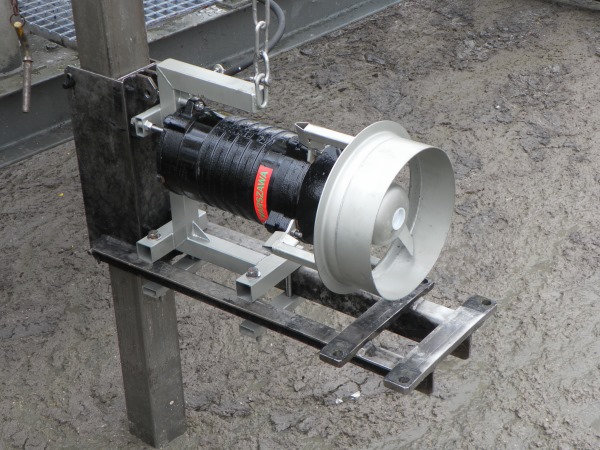

Mixer with protective ring

Mixer with protective ring

Propeller mixer

Propeller mixer

Metalchem-Warszawa S.A. using his extensive experience in the production of submersible pumps and constructions for the wastewater industry, resulting from many years of cooperation with various water suppliers, municipal units and waste utilization plants, he developed his own wastewater mixer constructions. We offer propeller mixers mounted on masts and support structures as well as ejector mixers, which are usually placed at the bottom of tanks as independent devices. All our mixers have already been tested many times and have a number of advantages that will be described at each solution. We hope that we will convince you to try and apply them on your premises, and then share your opinion about them with us.

The purpose of our mixers

Submersible mixers cause stream mixing of the medium in the tank and are mainly used in sewage treatment plants. They are intended to set the fluid in motion, homogenize its composition, prevent sedimentation, cause a specific flow direction and liquid circulation in tanks, ditches and channels. They are also often used in sewage aeration chambers as a support for intensifying oxygen absorption.

Propeller mixers MM

General characteristics of propeller stirrers for wastewater

- Metalchem-Warszawa 3-blade propellers for sewage mixers are characterized by high hydraulic efficiency and have self-cleaning ability.

- Wszystkie mieszadła mogą być wyposażone dodatkowo w pierścień ochronny wzmacniający hydrauliczny efekt mieszania.

- The motor for direct drive with the number of poles from 4 to 8, for continuous operation S1 and class F windings, has a temperature limiter in three phases of the stator windings and a humidity switch. This excludes the possibility of damage to the engine in the event of overloading or moisture ingress.

- The electric motor is sealed with a double mechanical seal in the oil chamber.

- Submersible sewage mixers are designed for work in liquids with a maximum temperature of 40 ° C, with immersion to a depth of 10m.

- The stirrer is standard equipped with a 10 m long neoprene sheath cable.

Code for the type of propeller stirrer

| MM | – | 15 | 6 | P |

| 1 | 2 | 3 | 4 |

- Propeller mixer for sewage produced by Metalchem-Warszawa S.A.,

- Motor power in kW (including one decimal place),

- Number of poles (indicates the rotational speed of the stirrer),

- Ring (no “P” means no ring).

Example of a designation: MM-226P

93/5000 Propeller mixer for sewage with 2.2 kW power with a 6-pole motor and a protective ring.

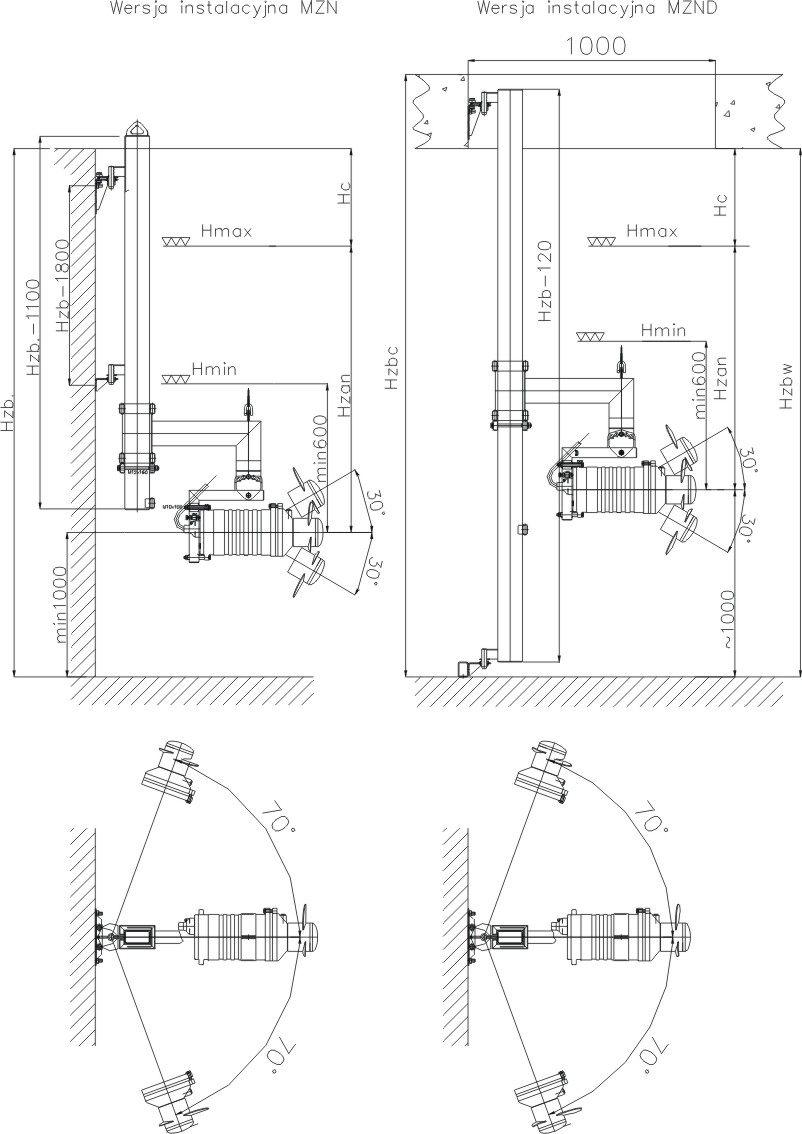

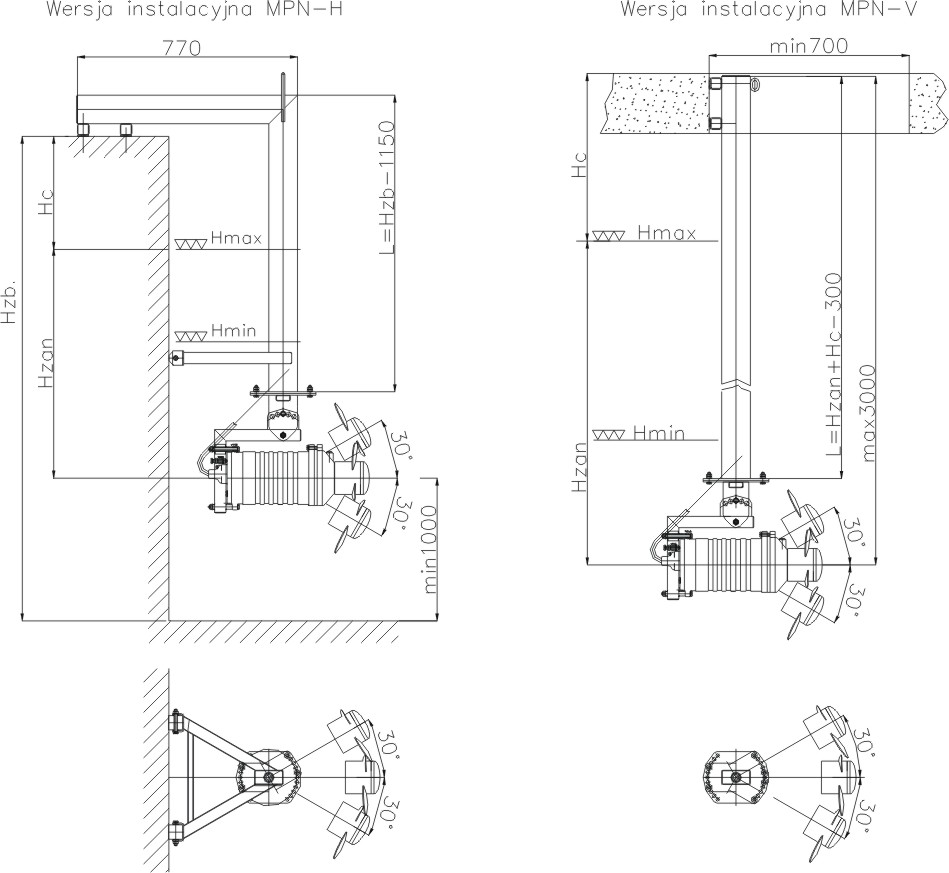

A typical stirrer casing consists of installing a vertical mast and a slider attached to the agitator that moves on the mast. It is then possible to adjust the working height of the sewage stirrer and by means of a mast to set the direction of the propeller stirrer in the sewage. Below are typical installation versions. We also offer many unusual solutions, as well as often clients use propeller mixers of our production as replacements for expensive mixers from foreign manufacturers.

Series of wastewater mixers from Metalchem-Warszawa S.A.

| No. | Mixer | Power [kW] | n [rpm] | I [A] | F [N] |

| 1 | MM-116 | 1,1 | 945 | 2,9 | 190 |

| 2 | MM-116P | 1,1 | 945 | 2,9 | 230 |

| 3 | MM-118 | 1,1 | 705 | 3,4 | 190 |

| 4 | MM-118P | 1,1 | 705 | 3,4 | 250 |

| 5 | MM-156 | 1,5 | 945 | 3,9 | 330 |

| 6 | MM-156P | 1,5 | 945 | 3,9 | 400 |

| 7 | MM-226 | 2,2 | 930 | 5,9 | 390 |

| 8 | MM-226P | 2,2 | 930 | 5,9 | 470 |

| 9 | MM-304 | 3,0 | 1415 | 6,6 | 450 |

| 10 | MM-304P | 3,0 | 1415 | 6,6 | 510 |

| 11 | MM-404 | 4,0 | 1415 | 9,2 | 630 |

| 12 | MM-404P | 4,0 | 1415 | 9,2 | 770 |

Installation kits:

In order to adapt to different customer needs, we offer different installation versions of tank mixers:

- MZN – adjustable stirrer, used in open tanks, pivotally mounted to a vertical wall allows setting the flow direction:

– in the horizontal plane: +/- 70°

– in the vertical plane: +/- 30° - MZND – adjustable stirrer supported on the bottom, used in covered or open tanks with platforms, pivotally mounted to the vertical wall of the mounting hatch or platform and to the bottom of the tank, allows setting the direction of the stream:

– in the jorizontal plane: +/- 70°

– in the vertical plane: +/- 30

- MPN-H – adjustable fixed stirrer, used in open tanks, rigidly attached to the horizontal wall of the tank crown, allows setting the flow direction:

– in the horizontal plane: +/- 70°

– in the vertical plane: +/- 30 - MPN-V – adjustable stirrer, used in open or open tanks with platforms, rigidly attached to the vertical wall of the mounting hatch or platform, allows setting the flow direction:

– in the horizontal plane: +/- 70°

– in the vertical plane: +/- 30

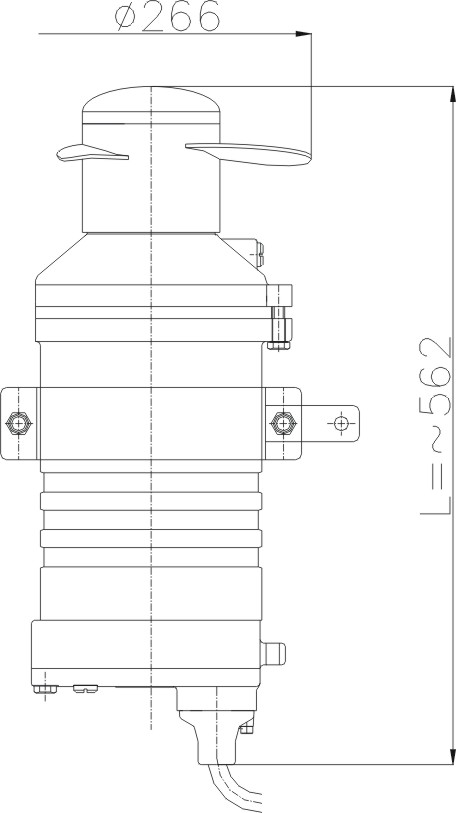

Mixer dimensions

Ejector mixers for sewage MME

Due to the constantly growing demand for stirrer with a highly concentrated stream and high efficiency of mixing, we offer you a range of ejector mixers based on submersible pumps we manufacture. Their simple design allows quick installation in the tank and directing the nozzles in several different, well-defined directions. The lack of moving and complicated elements apart from the submersible pump means that in the event of a failure we have an easily accessible service and we can eliminate long downtimes.

Ejector mixers can be used for all types of medium, such as sewage, stormwater / rainwater, river or lake water, slurry, leachate, rinse, etc. solids in a mixed medium.

In the case of a more aggressive medium or the content of abrasive particles, e.g. sand, please contact us and determine the appropriate protection of the stirrers, e.g. by appropriate covering of the pump components.

At the moment, all erection mixers we offer are selected individually to meet the needs of users, so if you need, please contact our Technical Department and choose the right construction for your tanks.