Purpose of network sewage pumping stations

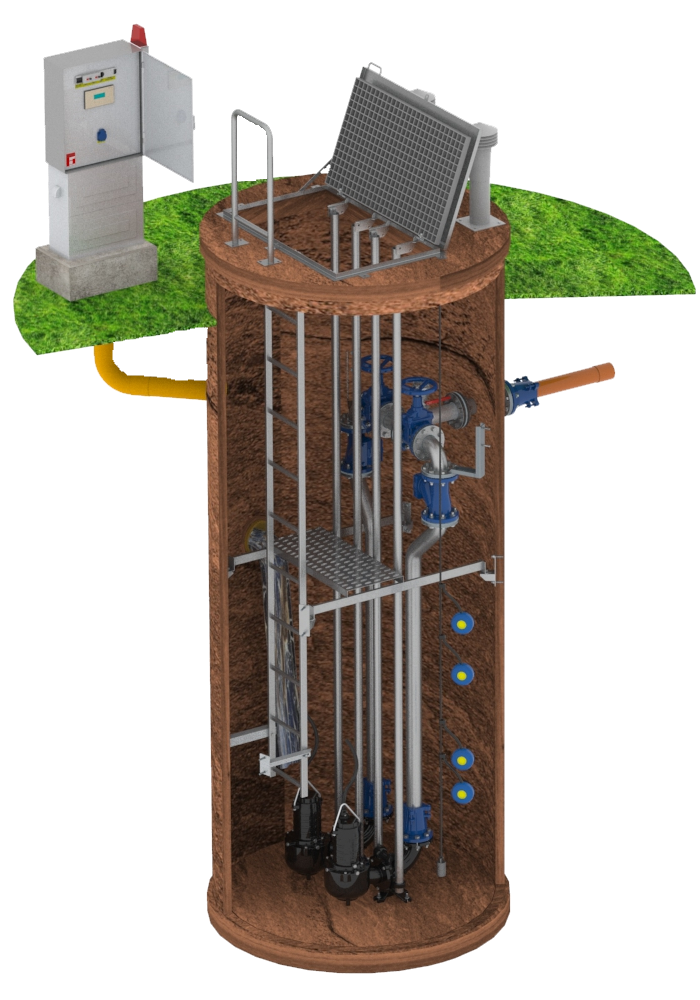

METALCHEM-WARSZAWA S.A. offers modern complete tank pumping stations for municipal and industrial sewage, rainwater, as well as for technological processes in sewage treatment plants and waste utilization and storage plants. Depending on the application and expected performance, we use one, two, three and multi-pump pumping stations. We can also divide them into municipal sewage pumping stations (with predictable and regular inflow), rainwater (large and irregular inflow) and process (controlled according to the client’s special guidelines or with dosing systems).

Complete sewage pumping stations offered by Metalchem-Warszawa S.A .:

- Tank made of: KBZ (concrete), PMB (polymerconcrete), PEHD (high density polyethylene) i TWS (synthetic fibers reinforced with fiberglass),

- Submersible pumps – with a range from 1.1kW to 22kW produced by METALCHEM-WARSZAWA S.A. or up to 50kW from other manufacturers,

- Supply and control switchboard – produced by METALCHEM-WARSZAWA S.A..,

- Medium level signaling unit – float set or hydrostatic probe (secured with two floats Suchobieg & Alarm),

- Stop and return fittings – valves (ball, less often flap) and gate valves (wedge with rubber or knife),

- Discharge pipelines int. tank – depending on the size and capacity of the pumps: Dn50, Dn65, Dn80, Dn100, Dn125, Dn150, Dn200, Dn250 or Dn300 made of stainless steel (304, 316 / 316L).

- Support structures and ensuring safety

and ease of use – service platforms, top covers with manholes locked with a padlock or key, handrails, ladders to the bottom of the tank, ventilation chimneys, fittings supporting elements, flushing connectors, inflow deflectors, bringing knobs to ground level, - Equalizer connections ,

- Assembly and delivery to the construction site – as agreed with the investor.

- Service platforms – we use in all of our facilities over 3-3.3m high and above 1200mm in diameter. The tilting platforms used in pumping stations allow the user to operate the shut-off and return valves safely and, if necessary, go down the ladder to the bottom of the tank.

- Pumps are pulled out after two widely spaced guides to the top , which facilitates their reinstallation even in the case of a completely flooded pumping station, and when lowering, the pump always settles properly on the coupling knee (without turning and special aiming of the catch ).

- Pumping covers METALCHEM-WARSZAWA have an internal safety grille, enabling pumping ventilation at the same time protecting against falling in, directly after opening the hatch (loss of consciousness due to vapors from the tank) or by carrying out work around the tank cover.

- Double gravitational ventilation ensures continuous circulation and air exchange. Ventilation chimneys (long and short) can be equipped with anti-odor filters with a BIOFILTR type insert or ACTIVE CARBON on customer’s request.

- Sealed cable entries in the switchgear eliminate the possibility of damage to the vapor control systems from the tank,

- Support structures , pump chains and screw joints are made of stainless steel, thanks to which their durability in an aggressive sewage environment is many years,

- Rinsing circuit – manual or automatic (MASP) for moving sediments and breaking the scum in the tank. This facilitates self-cleaning of the pumping station from accumulated sand, grease and all kinds of sludge.

- In underroad sewage pumping stations, access to pumps is difficult, so depending on the size of containers and pumps, we use one, two or more channel manholes with a diameter of min. 800 mm.

- The METALCHEM-WARSZAWA pumping stations, thanks to their unique design, provide comfort to the user, the pumps are lowered along the guides pulled out under the manhole cover.

- The manholes we use have a hinge and, optionally, a key or bolt lock, which prevents them from opening under the influence of vehicle traffic above them. The most commonly used hatches are round Ø800, square 800×800 and rectangular hatches 600×900. All hatches are of class D400.

- Shutter knobs are available from the level of the service platform as in free-standing pumping stations (see restrictions due to tank diameter and height). It is also possible to bring out the knob knobs so that they are accessible from ground level after removing the manhole or in separate street boxes next to the manhole.

- The switchboard is placed at a safe distance from the tank, outside the vehicle exposure zone.

- At the request of the customer in the switchboard and under the manhole it is possible to install a burglary sensor (facility opening).

- With the appropriate height between the ground and the tank hidden underground, it is possible to build a portable crane foot in the street box, which greatly facilitates pulling out the pumps.

Free-standing sewage pumping stations

Underroad sewage pumping stations

In the event that sewage pumping stations have to be built up along a communication route such as: street, maneuvering area or pavement, the tank cover is placed under the terrain and only the sewer manhole remains on a par with the ground surface. Such tanks have a reinforced structure to carry higher loads and better dampen vibrations caused e.g. by car traffic.